© 2025 ALM Global, LLC, All Rights Reserved. Request academic re-use from www.copyright.com. All other uses, submit a request to [email protected]. For more information visit Asset & Logo Licensing.

Trending Stories

Events

- GlobeSt. Multifamily Spring 2025 April 01, 2025 - New YorkJoin the industry's top owners, investors, developers, brokers & financiers at THE MULTIFAMILY EVENT OF THE YEAR!More Information

- GlobeSt. Net Lease Spring 2025 April 01, 2025 - New YorkThis conference brings together the industry's most influential & knowledgeable real estate executives from the net lease sector.More Information

- Real EstateGlobeSt. ELITE Women of Influence (WOI) 2025July 21, 2025 - DenverGlobeSt. Women of Influence Conference celebrates the women who drive the commercial real estate industry forward.More Information

Recommended Stories

More Multifamily Loan Originations Expected in 2025

By Philippa Maister | January 10, 2025

Despite short-term pressures, multifamily would remain “a favored asset class.”

Office Market Sees First Positive Net Absorption Since 2021

By Erika Morphy | January 10, 2025

Leasing = hits post-pandemic record for third consecutive quarter amid shifting strategies.

Last Day to Nominate for Net Lease Influencers!

By Ingrid Tunberg | January 10, 2025

Submit a nominee for GlobeSt.'s 2025 Influencers in Net Lease recognition before the extended deadline on January 10th!

Resource Center

Assessment

Sponsored by Cherre

Data Management Scorecard: A Health Check for Your Data Management Capabilities and Challenges

CRE strategies and business decisions are only as strong as the data that powers them, and that data better be correct. This self-assessment will help you gauge your current data management capabilities.

Assessment

Sponsored by Cherre

Data Management Scorecard: A Health Check for Your Data Management Capabilities and Challenges

CRE strategies and business decisions are only as strong as the data that powers them, and that data better be correct. This self-assessment will help you gauge your current data management capabilities.

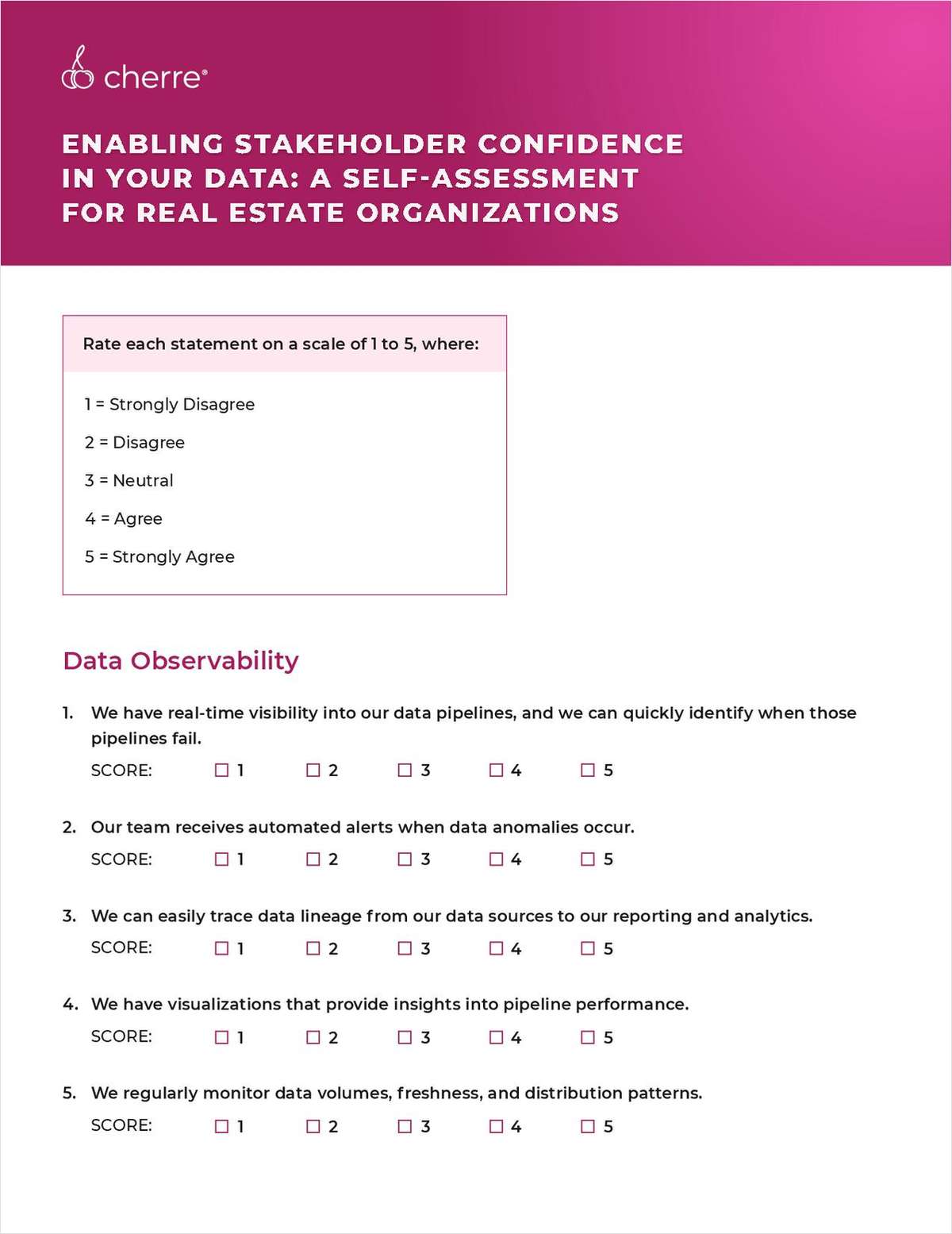

Assessment

Sponsored by Cherre

Enabling Stakeholder Confidence in Your Data: A Self-Assessment for Real Estate Organizations

Does your data inspire confidence or is there a significant lack of trust in its validity? Use this assessment to gauge where your organization’s data practices are at today and what gaps exist.